SABIN® Polycarbonate sheets from Sabin Engineering provide several benefits such as high optical quality and strength. They are also highly resistant to impact and fire. The sheets are used in both interior and exterior applications, and help in converting an architect’s vision into reality.

SABIN® Polycarbonate sheets are of high optical quality. They can be used in signage products for a variety of advertising applications such as POS stands, signboards, POP display boards in shops and outdoor poles. SABIN® Polycarbonate sheets are also available in a variety of textures and surface patterns for the lighting industry.

SABIN® Polycarbonate sheets used in building construction effectively block UV radiation and infrared heat waves. The sheets achieve good sound insulation while allowing good light transmission to conserve energy. SABIN® ’s UV coated Polycarbonate sheets are also resistant to yellowing caused by aging. Additional details are available in the product warranty card.

SABIN® Polycarbonate sheets can be easily cold formed into gentle curves up to 175 times the sheet thickness. They can also be bent up to 90 degrees by workshop tools. The sheets weigh 1.2 kg/m2/mm whereas glass weighs 2.5 kg/m2/mm; hence, these sheets are lighter than glass by 50%.

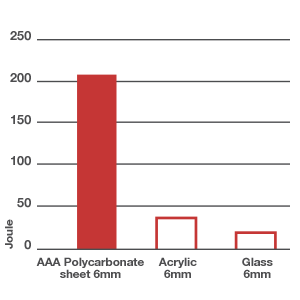

The sheets can further be thermoformed without losing their UV resistance property. They are 250 times stronger than regular glass and 30 times stronger than acrylic. The service temperature of the sheets ranges between -40 to +120oC.

| Thickness mm | Polycarbonate kg/m2 | Glass kg/m2 |

|---|---|---|

| 2 | 2.4 | 5 |

| 2.4 | 2.88 | 5.9 |

| 3 | 3.6 | 7.8 |

| 4.5 | 5.4 | 11.7 |

| 6 | 7.2 | 15.6 |

| 9.5 | 11.4 | 23.4 |

| Feature | Method | Value | Unit |

|---|---|---|---|

| Mechanical | |||

| Tensile modulus | ISO 527-1-2 | 2349 | MPa |

| Yield stress | ISO 527-1-2 | >60 | MPa |

| Yield strain | ISO 527-1-2 | 6 | % |

| Charpy impact strength | ISO 179-leU | No breakage | kJ/m2 |

| Charpy impact strength | ISO 179-leA | 79 P | kJ/m2 |

| Nominal strength at break | ISO 527-1-2 | >49 | % |

| Flexural modulus | ISO 178 | 2349 | MPa |

| Flexural strength | ISO 178 | 89 | MPa |

| Physical | |||

| Density | ISO 1183 | 1.20 | g/cm3 |

| Water absorption equilibrium | ISO 62, 23°C, 50% relative humidity | 0.13 | % |

| Water absorption saturation | ISO 62, 23°C | 0.34 | % |

| Module shrinkage | Sabin Engineering test | 0.6-0.8 | % |

| Thermal | |||

| VICAT Softening temperature | ISO 306, 50 N, 50°C/h | 147 | °C |

| Thermal conductivity | ISO 8302 | 0.2 | W/m°C |

| Coefficient of linear thermal expansion | ISO 11359-2, 23-80°C | 7 | ×10-4/°C |

| Temperature of deflection under load | ISO 75-1-2, 1.80 MPa | 127 | °C |

| Temperature of deflection under load | ISO 75-1-2, 1.45 MPa | 141 | ×10-5/C |

These data correspond to raw material values